Product Industry Knowledge

The Application of plastic Child Plastic-resistant Caps in Medical Cannabis Packaging

Plastic Child Resistant Caps play a crucial role in medical cannabis packaging, ensuring the safe and compliant storage of cannabis products while protecting both patients and the wider community.

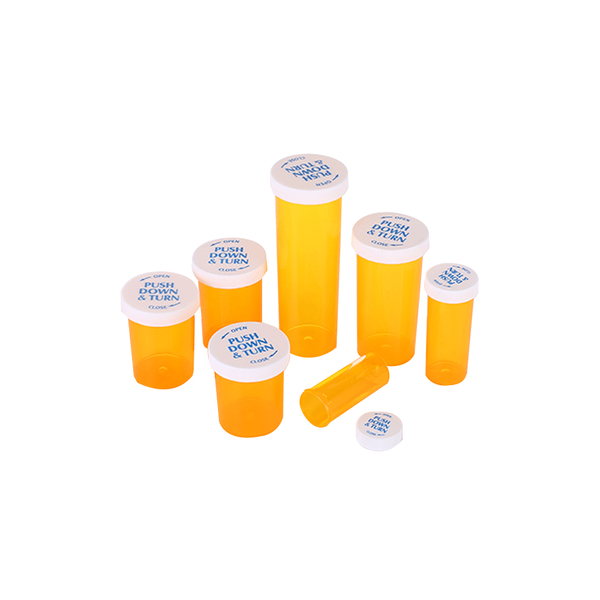

Child Safety Compliance: Regulatory agencies often mandate child-resistant packaging for medical cannabis products to prevent accidental ingestion by children. Plastic Child Resistant Caps are designed with mechanisms that make them challenging for young children to open. They require a specific combination of actions, such as pushing and turning, which most children cannot perform, thereby reducing the risk of unintentional consumption.

Preservation of Product Quality: Medical cannabis products, including flower buds, oils, and edibles, are sensitive to environmental factors like moisture and oxygen. Child Resistant Caps create an airtight seal that helps maintain the product's freshness, potency, and quality by preventing air and moisture from entering the container.

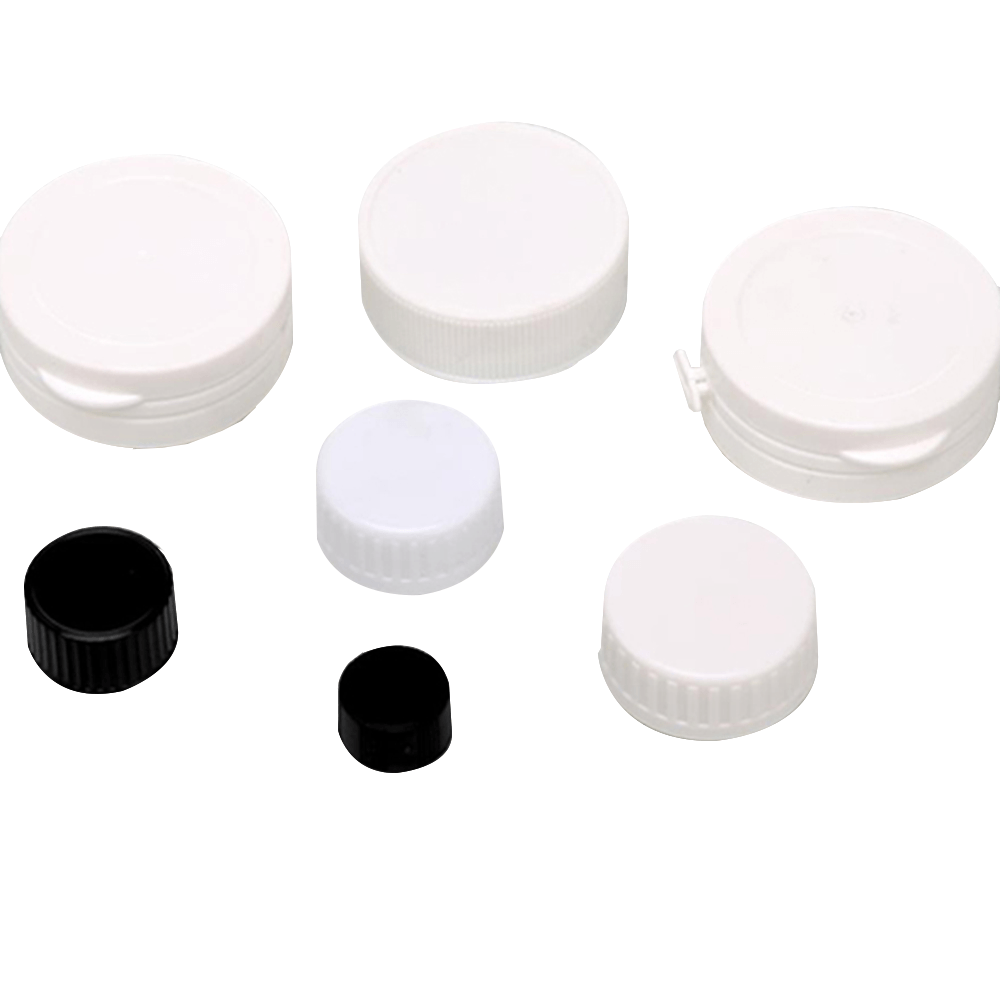

Diverse Product Types: Medical cannabis products come in various forms, from oils and tinctures to edibles and capsules. Plastic Child Resistant Caps are versatile and can be customized to fit different packaging needs, accommodating various container sizes and shapes.

Easy Access for Patients: While Child Resistant Caps provide robust safety features, they are designed for adult accessibility. Patients with medical conditions that require cannabis for treatment need packaging that can easily open and close, and these caps strike a balance between safety and ease of use.

Branding and Labeling: Child Resistant Caps can be customized with branding, labels, and essential product information. This branding opportunity not only enhances product recognition but also helps in compliance with labeling regulations.

Compliance with Regulations: Compliance with regulations is paramount in the medical cannabis industry. Plastic Child Resistant Caps are designed and tested to meet strict regulatory standards, ensuring that medical cannabis products meet safety requirements.

The application of plastic Child-resistant caps in medical cannabis packaging addresses critical safety concerns, ensures product quality and integrity, provides accessibility for patients, and aids in regulatory compliance. These caps are a vital component of responsible and compliant medical cannabis packaging, promoting safe and effective use for patients in need of this therapeutic option.

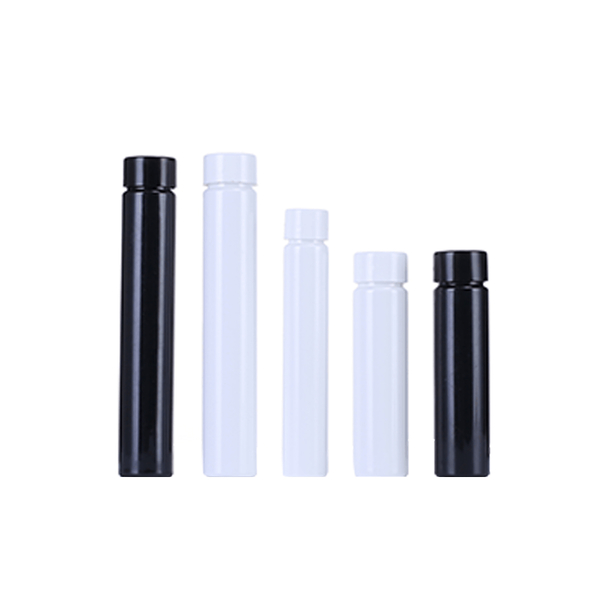

Specifications of Child-resistant Push-and-turn Plastic Caps

Child-resistant push-and-turn plastic caps, often referred to as CRC (Child-Resistant Closure) caps, are designed to provide a high level of safety and security in the packaging of various products, particularly in industries where child safety is a primary concern. These caps are engineered to be challenging for young children to open while remaining accessible for adults. Here are some key specifications and features of child-resistant push-and-turn plastic caps:

1. Material:

Child-resistant push-and-turn caps are typically made from high-quality plastic materials, such as polypropylene (PP) or polyethylene (PE). These materials are known for their durability and resistance to moisture and chemicals, ensuring the integrity of the contents within.

2. Push-and-Turn Mechanism:

The defining feature of these caps is the push-and-turn mechanism. To open the cap, users must press down on the cap while simultaneously turning it in a specific direction. This combination of movements is designed to be challenging for children but manageable for adults.

3. Tamper-Evident:

Many child-resistant push-and-turn caps are equipped with tamper-evident features. These features provide visual cues to consumers, indicating whether the cap has been previously opened or tampered with.

4. Customizable:

Manufacturers can customize these caps to meet specific requirements. This includes the choice of plastic material, cap size, and color. Caps can also be designed to accommodate different neck finishes of bottles or containers.

5. Compliance:

Child-resistant push-and-turn caps are designed to meet regulatory standards for child-resistant packaging in various industries. Compliance with safety regulations is essential, particularly in the pharmaceutical, cannabis, and chemical sectors.

6. Versatile Applications:

These caps are suitable for a wide range of products, including medications, household chemicals, cannabis products, and more. They provide a versatile and reliable solution for industries where product safety is paramount.

7. Child-Resistant Certification:

Manufacturers often subject their child-resistant caps to rigorous testing and certification processes to ensure they meet specific safety standards. Certifications may vary depending on regional or industry-specific requirements.

8. Easy for Adults:

While designed to be child-resistant, these caps are engineered to be straightforward for adults to open. The push-and-turn mechanism is intuitive and does not require excessive force, ensuring accessibility for those who need to access the contents.

Child-resistant push-and-turn plastic caps are an integral part of safety packaging solutions in various industries. Their specifications are carefully designed to strike a balance between safety for children and usability for adults, making them a vital component of child-resistant packaging systems.

English

English Español

Español

+86-576-84308078

+86-576-84308078

289 Lvting Road, Huangyan District, Taizhou City, Zhejiang Province 318020, PR China

289 Lvting Road, Huangyan District, Taizhou City, Zhejiang Province 318020, PR China