#FDA & LFGB Compliant Clarified Polypropylene.

#Available in Clear or UV resistant colors

.Airtight, leak proof. Moisture Resistant

Packed in plastic bags.

#FDA & LFGB Compliant Clarified Polypropylene.

#Available in Clear or UV resistant colors

.Airtight, leak proof. Moisture Resistant

Packed in plastic bags.

|

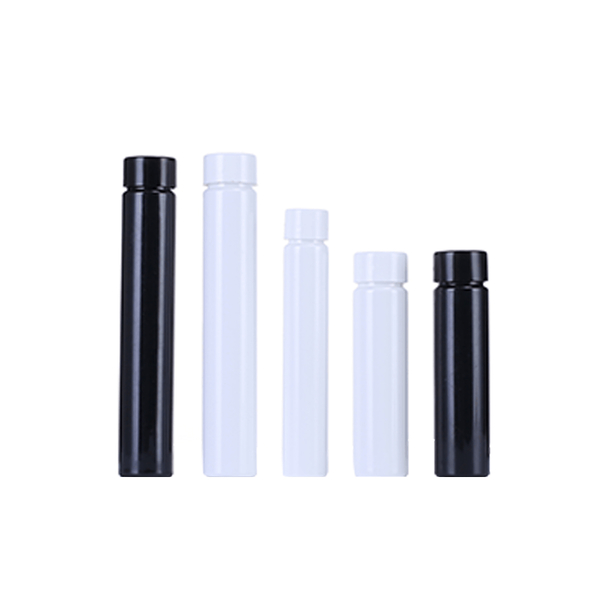

SKU# |

DT92 |

DT125 |

|

Tube Length (mm) |

92mm |

125mm |

|

QTY/BOX |

1000 |

600 |

|

Color |

Transparent Colors Available : Clear/ Amber/Red/Purple/Blue/Green/Smoke Opaque Colors Available: Opaque White/ Opaque Green/ Opaque Blue/ Opaque Purple/ Opaque Black /Opaque Golden/ Opaque Silver |

|

|

Material |

Polypropylene |

|

|

Total Height (mm) |

105.75mm |

137.17mm |

|

Cap Height (mm) |

20.2mm |

20.2mm |

|

Cap Diameter (mm) |

15.85mm |

15.85mm |

|

Tube Diameter - Upper Outside (mm) |

16.02mm |

16.55mm |

|

Tube Diameter - Lower Outside (mm) |

15.2mm |

14.85mm |

|

Tube Diameter - Upper Inside (mm) |

14mm |

14mm |

|

Tube Diamter - Internal (mm) |

14.2mm |

14.3mm |

|

Max Label Size Diameter (mm) |

56mm x 77mm |

58mm x 105mm |

Dewei Plastics Ltd. is a well-established manufacturer with over 20 years of experiences specializing in manufacturing various containers for pharmacies and many other packaging usages. We provide a complete services and products to hundreds of our global clients, from product design, development to manufacturing. Our team has a strong CAD design and development expertise to meet all customers' requirements for rapid and accurate development and efficient manufacturing. We mainly provide high-quality plastic products and services for US and European markets, such as packaging plastic bottles, cans, tubes, vials and many others. The main feature of our product is a reliable and consistent child-proof safety structure, which meets the requirements of European and American child protection laws and regulations. As OEM Marijuana Packaging DOOB Tubes Manufacturers and custom Plastic DOOB Tubes Suppliers, Dewei has established a complete set of quality management system which is strictly in accordance with the ISO9001 standards and certified for ISO9001 certification. Adhering to our service concept of "outstanding design, honest service, excellent quality, and competitive pricing", we meet continuously improving product and service requirements of different customers. Dewei has more than 20 automated production equipment and clean workshops. Our monthly production capacity reaches more than 50 standard containers to meet customers' requirements for quick delivery and a short lead time. Dewei is conveniently located at Huangyan District in Taizhou City, Zhejiang Province, the famous coastal city for plastics and molds manufacture in China, with convenient transportation to the world. We are within 2 miles / 3 km away from Taizhou Bullet Train Station, and 10 miles /15 km to Taizhou Airport, and 3 hours to Shanghai by trains. All guests and clients, from home and abroad, are welcome to visit us.

DeWei Plastic Factory was

established in 1998.

DeWei has more than 20 advanced

automated production equipment.

The monthly production capacity can

reach more than 50 standard containers .

Choose comes from trust, and cooperation comes from honesty. Marijuana Packaging-DOOB Tubes Factory in China

look forward to working with you wholeheartedly.

#FDA & LFGB Compliant Clarified Polypropylene. #Available in Clear or UV resistant colors #Squeeze top side pop up . Child Resistant cap. .Airtigh

#FDA & LFGB Compliant Clarified Polypropylene. #Available in Clear or UV resistant colors .Airtight, leak proof. Moisture Resistant Packed in plas

#FDA & LFGB Compliant Clarified Polypropylene. #Available in Clear or UV resistant colors #Screw top tube . NOT Child Resistant cap. .Airtight,

- Airtight, Moisture Resistant, and Odor Proof Design.- FDA Compliant Clarified Polypropylene.- Available in Clear or UV resistant colors- Squeeze top

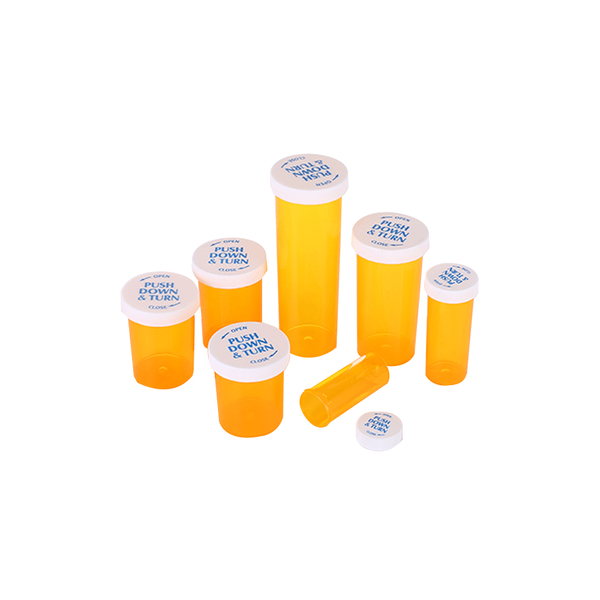

Reversible Cap Vials got its name from the dual purpose cap. It offers a Push-down and turn option to open and close the container, also known as chil

-FDA & LFGB Compliant Clarified Polypropylene.-Available in Clear or UV resistant colorsPush Tab down and Turn Caps. Child Resistant and Easy open

-Airtight, Moisture Resistant, and Odor Proof Design.-FDA & LFGB Compliant Clarified Polypropylene.-Available in Clear or UV resistant colorsPush

-Airtight, Moisture Resistant, and Odor Proof Design. -FDA Compliant Clarified Polypropylene. -Available in Clear or UV resistant colors -Squeeze top

If you’re looking for an inconspicuous container for your vape pen cartridges, look no further. This Vape Container raises no suspicions as it’s u

-FDA & LFGB Compliant Clarified Polypropylene and Polyethylene -Available Color : Opaque White and Opaque Black Push Down and Turn cap ,Child Resi

These were for retail marijuana, medical marijuana medication, or for tamper proofing concentrate containers for wax, dabs, and oil concentrates-Good

#FDA & LFGB Compliant Clarified Polypropylene.#Available in Clear or UV resistant colorsEasy close and open Snap cap.Airtight, leak proof. Moistur

The development of doob tubes in today's society is influenced by a combination of factors, including changes in cannabis laws and regulations, environmental concerns, consumer preferences, and advancements in packaging technology.

Legalization of Cannabis: The increasing legalization of cannabis in various regions and countries has significantly influenced the development of doob tubes. In legal cannabis markets, there are often strict regulations governing the packaging of cannabis products, including pre-rolled joints. This has driven innovation in packaging design and materials to meet compliance requirements.

Environmental Sustainability: Environmental consciousness is a growing concern in modern society. As a result, there is a push for more eco-friendly packaging solutions, including doob tubes made from recyclable or biodegradable materials. Manufacturers are exploring ways to reduce the environmental impact of packaging while still meeting regulatory standards.

Customization and Branding: Cannabis businesses are increasingly focusing on branding and marketing efforts. Customizable doob tubes allow companies to showcase their branding, logos, and unique designs. Creative packaging can help differentiate products in a competitive market.

Safety and Child-Resistance: Safety remains a top priority, especially in markets where cannabis products are legal. Child-resistant features are essential for packaging, and manufacturers continue to innovate in this area to ensure compliance and product safety.

Advanced Materials: Advancements in materials science have led to the development of more robust and protective packaging materials. Manufacturers are exploring materials that are not only durable but also capable of preserving the freshness and potency of the cannabis inside.

Consumer Convenience: Convenience is a key driver in packaging design. Manufacturers are looking for ways to make doob tubes more user-friendly and convenient for consumers, whether through easy-open caps, tamper-evident seals, or other features.

Regulatory Compliance: Cannabis regulations vary widely from one jurisdiction to another. Packaging requirements can change frequently as laws evolve. This necessitates flexibility and adaptability in the design and production of doob tubes to meet evolving regulatory demands.

Technology Integration: Some doob tubes now incorporate technology, such as QR codes, to provide consumers with access to detailed product information, including strain details, lab test results, and more. This enhances transparency and consumer education.

Market Diversity: The cannabis market is diverse, catering to both medical and recreational consumers. Doob tubes must accommodate various product types, including CBD joints, THC joints, and specialty strains.

The development of doob tubes in today's society is shaped by a combination of legal, environmental, technological, and consumer-driven factors. As the cannabis industry continues to evolve, so too will the design and functionality of doob tubes to meet the changing needs and expectations of both consumers and regulators.

A plastic pre-roll doob tube is a small, cylindrical, and airtight container made of plastic, typically designed to store and protect pre-rolled cannabis. These tubes are commonly used in the cannabis industry and have several key characteristics:

Material: Plastic pre-roll doob tubes are typically made from polypropylene or other durable plastic materials. Polypropylene is known for its resistance to moisture and odor, making it ideal for storing cannabis products.

Size: These tubes come in various sizes to accommodate different joint lengths and diameters. Common sizes include 78mm, 90mm, and 116mm, although custom sizes are also available.

Airtight Seal: One of the primary purposes of a doob tube is to provide an airtight and moisture-resistant seal. This helps preserve the freshness and potency of the pre-rolled joint inside while also containing any odors.

Child-Resistant Cap: In many regions where cannabis is legal, pre-roll doob tubes are required to have child-resistant caps. These caps often require a combination of squeezing and turning to open, making them difficult for children to access.

Visibility: Some doob tubes are transparent, allowing consumers to see the contents, which can be helpful for product inspection and branding.

Labeling and Branding: Pre-roll doob tubes often have space for labels, branding elements, and strain information. Compliance labels may also be included to meet regulatory requirements.

Convenience: Pre-roll doob tubes are convenient for consumers because they are portable and protect the pre-rolled joint from damage, moisture, and odors. They are also discreet and can easily fit in a pocket or purse.

Quantity: These tubes are often sold in bulk to cannabis producers, dispensaries, or retailers, allowing them to package and sell their pre-rolled joints in a standardized and compliant manner.

Plastic pre-roll doob tubes play an important role in the cannabis industry by ensuring that pre-rolled joints are delivered to consumers in a safe, convenient, and compliant manner. They help maintain product quality and freshness while also providing a means for branding and product information dissemination.

+86-576-84308078

+86-576-84308078 [email protected]

[email protected] 289 Lvting Road, Huangyan District, Taizhou City, Zhejiang Province 318020, PR China

289 Lvting Road, Huangyan District, Taizhou City, Zhejiang Province 318020, PR China